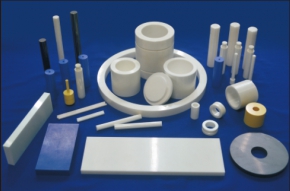

Boron Carbide Ceramics

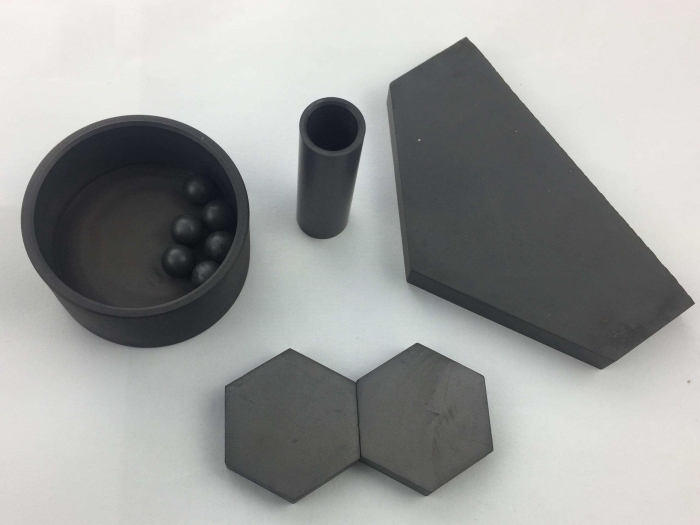

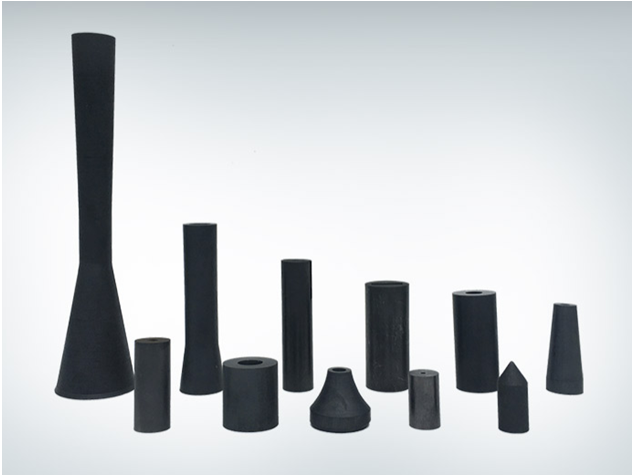

LongTek B4C ceramic parts with extreme abrasion resistance are ideal material for Sandblasting/abrasive slurry/ Armor protection

Boron carbide (also known as black diamond) is the third hardest material known – only diamond and cubic boron nitride are harder – giving it exceptional abrasion resistance.

Its outstanding hardness makes it a suitable abrasive powder for lapping, polishing and water jet cutting of metals and ceramics. The combination of low specific weight, high hardness and reasonable toughness makes it a suitable material for body and vehicle armor. Boron carbide is also extensively used as control rods, shielding materials and as neutron detectors in nuclear reactors due to its ability to absorb neutrons without forming long lived radionuclide.

Boron carbide ceramic components is a composite of boron carbide and silicon carbide which leads to an increase in strength and hardness as compared to other composite materials.

Properties:

Ø Low thermal conductivity

Ø Susceptible to thermal shock failure

Ø Outstanding hardness

Ø Extremely brittle

Ø Semiconductor

Ø Good thermal-neutron capture

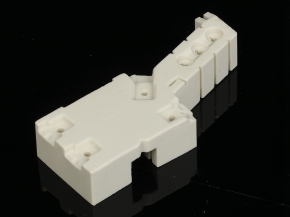

| Boron carbide bullet-proof vest: | |

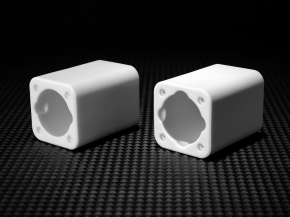

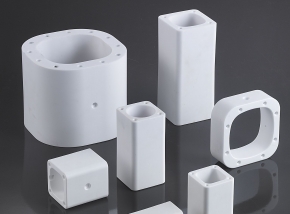

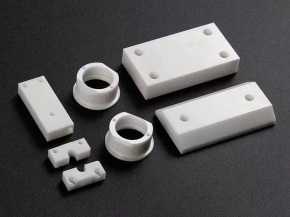

| Boron carbide seal ring: | |

| Boron carbide ceramic plate: | |

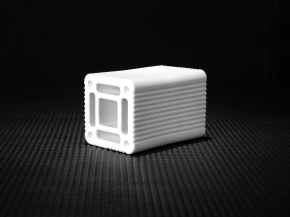

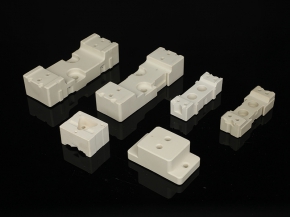

| Boron carbide spray nozzle: |