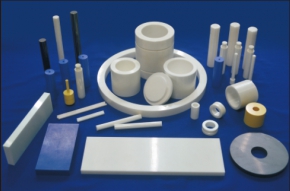

Silicon Carbide Ceramics

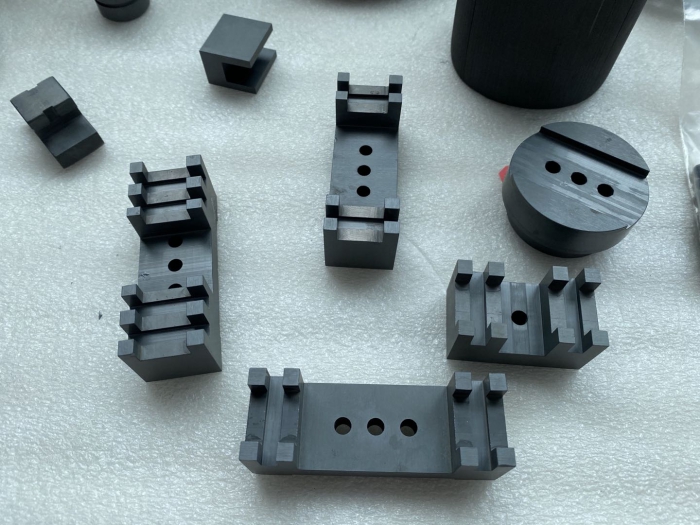

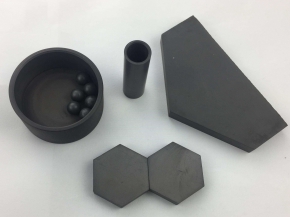

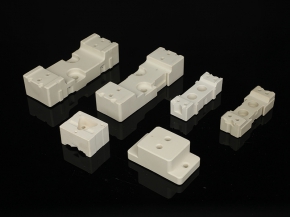

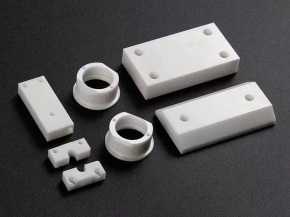

Silicon carbide ceramic, mainly consisting of SiC, is the most corrosion-resistant ceramic, mainly used as Armor Protection, Grinding Lining & Klin Furnature, mechanical seals and pump parts, etc.

Silicon carbide ceramic, mainly consisting of SiC, is the most corrosion-resistant ceramic, mainly used in Klin Furnature, mechanical seals and pump parts, etc.

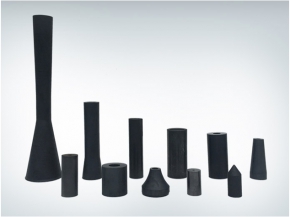

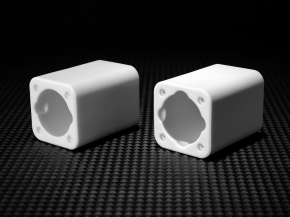

SINTERED SILICON CARBIDE (SSIC)

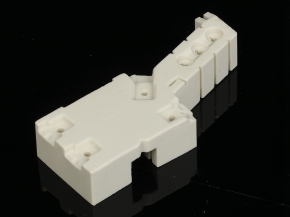

Sintered Silicon Carbide (SSiC) is produced using very fine SiC powder containing sintering additives. It is processed using forming methods typical for other ceramics and sintered at 2,000 to 2,200° C in an inert gas atmosphere. It is Silicon Carbide ceramics with higher performance.

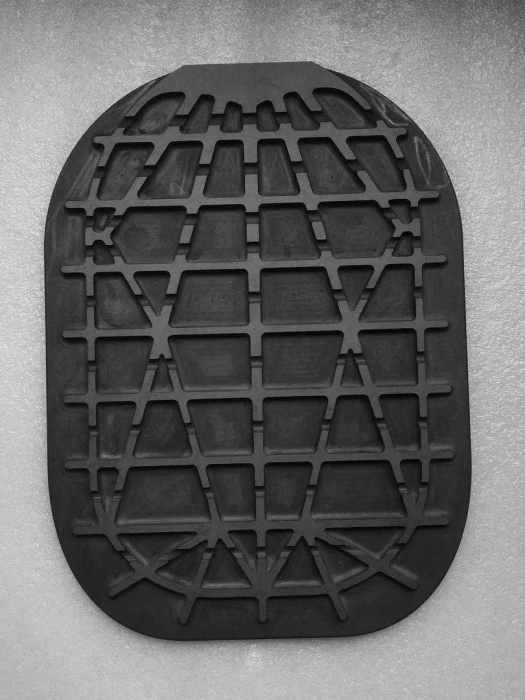

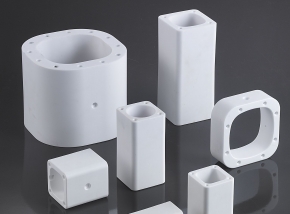

NITRIDE BONDED SILICON CARBIDE (NB SiC)

NB SiC is shaped by casting with composition of high pure SiC and Si powder, and sintered through nitrified reaction. It has higher strength than RB SiC and has excellent oxidation resistance. In additional to its structural propertieis, it also has excellent wear properties and is resistant to corrosion and erosion by molten metals, as well as excellent load bearing strength and resistance to chemical and abrasive attack.

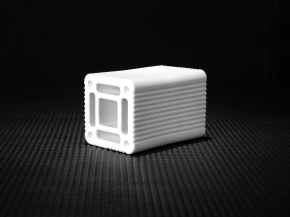

| Recrystallized SIC: | Nitride bonded SIC |

| Pressless SIC: | RSIC |

| NSIC: |