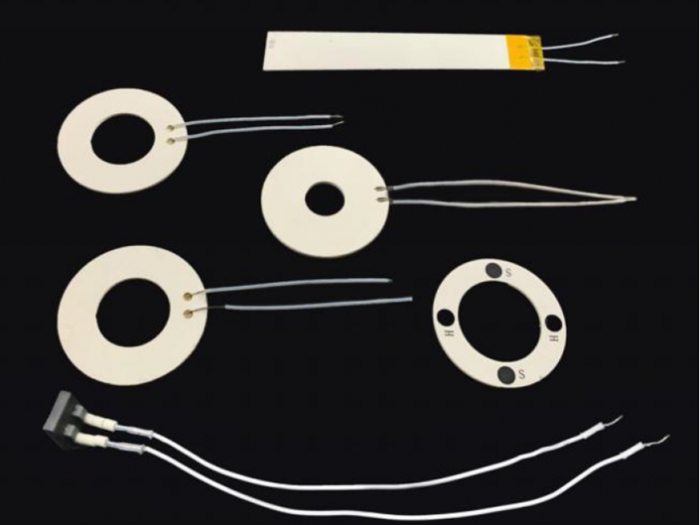

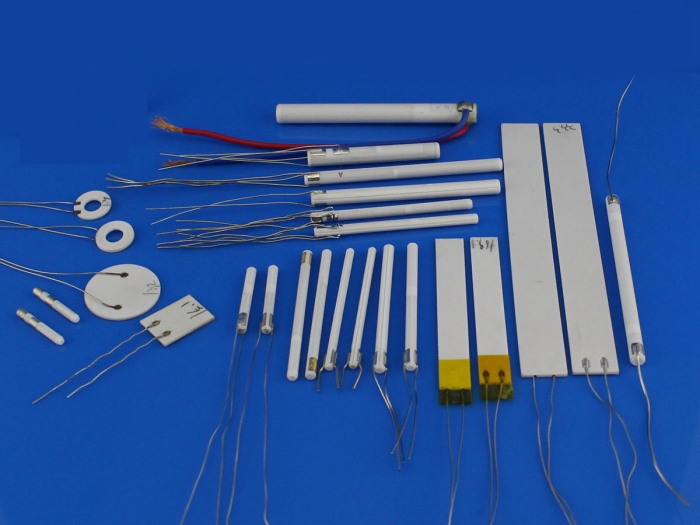

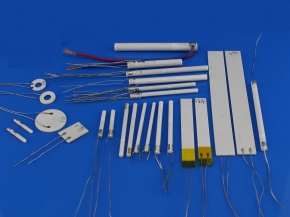

Ceramic Heater

Ceramic Heater's applications include use as innovative types of heaters in the automotive, medical and semiconductor industries

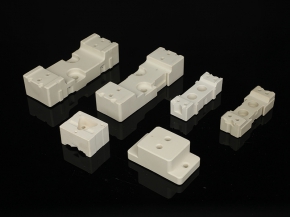

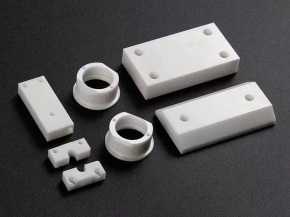

Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before. Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries.

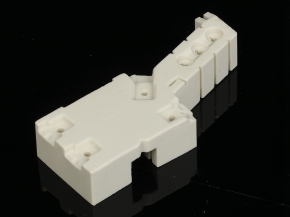

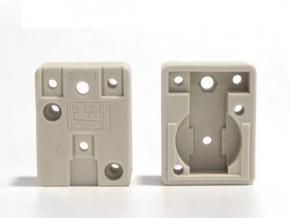

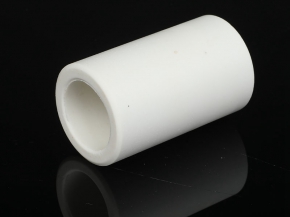

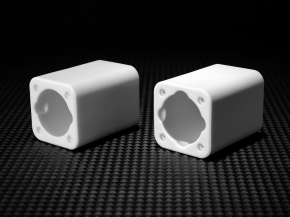

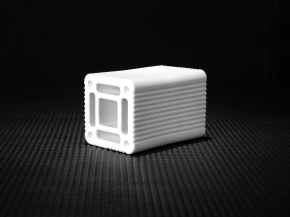

Heater Design Structure: The heating element of the ceramic heater is built into a substrate of alumina or silicon nitride material, then laminated and sintered into one piece — providing insulation and protection from the outside environment.

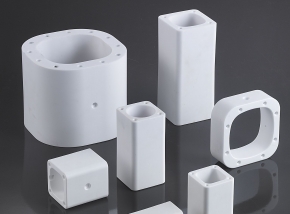

HTCC (High Temperature Co-Ceramics)

Advantages:

Customized solutions based on a variety of manufacturing processes

Efficient solutions due to high degree of design support from the beginning of the product development cycle

Availability of a variety of mechanical, thermal (ANSYS, ABACUS), optical (ZEMAX) and electrical (HFSS, ADS) simulation tools

Worldwide customer support from local manufacturing facilities with technical competence centers

Characteristics of HTCC:

Excellent mechanical stability

Easy integration into metal housings due to matched thermal coefficient of expansion

High thermal conductivity

Use of non-noble metal pastes

Additional plating reveals solderable and wirebondable surfaces

| ceramic material: | alumina |

| ceramic material: | Si3N4 |

| Application 1: | Glow Plug/Igniter/Heater for Oxygen Sensor |

| Application 2: | Industry heaters |